Uhlobo lokugcina olubandayo

Ngezinga lokushisa:

Izinga lokushisa eliphezulu lokugcina elibandayo (±5℃): lilungele ukulondolozwa kwezithelo nemifino.

Izinga lokushisa elimaphakathi (00℃~--5℃): lilungele ukudla okubandayo ngemva kokuncibilika.

Izinga lokushisa eliphansi lokugcina elibandayo - 20 ℃): lilungele ukukhiqizwa okuqandisiwe, ukudla kwenyama yenkukhu - 10 ℃ imikhiqizo yasemanzini.

23℃ Yesikhashana: ilungele ukuhlala isikhashana ngaphambi kwesitoreji esibandayo esilandelayo.

Ngevolumu:

Isitoreji esincane esibandayo:<500m³;

Isitoreji esibandayo sosayizi omaphakathi: 500~1000m³;

Isitoreji esikhulu esibandayo: >1000m³;

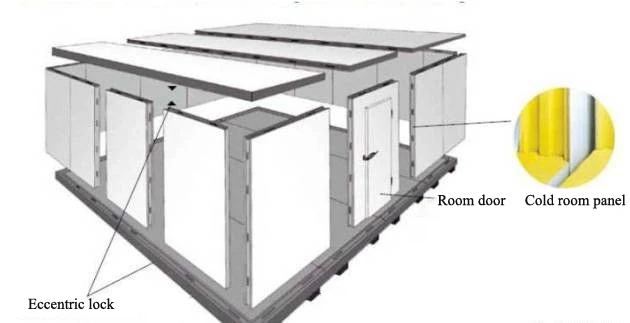

Isakhiwo kanye nemishini eyinhloko yokugcina amakhaza

Iphaneli: Ikhiqizwe ngaphambilini, enobude obunqunyiwe, ububanzi nobukhulu, okungakhethwa ngokuya ngezidingo zokufakwa kwegumbi elibandayo. Amapuleti anogqinsi oluyi-10 cm ngokuvamile asetshenziselwa ukugcinwa kwamakhaza aphakeme naphakathi nendawo, kanti amapuleti anogqinsi oluyi-12 cm noma u-15 cm ngokuvamile asetshenziselwa ukugcina izinga lokushisa eliphansi kanye nokugcinwa okuqandisiwe.

Isakhiwo kanye nemishini eyinhloko yokugcina amakhaza

Ngaphansi kwezimo ezijwayelekile, iziqandisi ezincane zisebenzisa ama-compressor we-hermetic ngokugcwele. Iziqandisi ezinosayizi omaphakathi ngokuvamile zisebenzisa ama-semi-hermetic compressor. Iziqandisi ezinkulu zisebenzisa ama-semi-hermetic compressor noma ama-screw compressor. Uma ukhetha, i-compressor yefriji ye-ammonia nayo ingacatshangelwa, ngoba i-compressor yefriji ye-ammonia inamandla amakhulu futhi ingasetshenziselwa izinhloso eziningi, kodwa ukufakwa nokuphatha kuyinkimbinkimbi kakhulu.

I-Evaporator:

Ngaphansi kwezimo ezijwayelekile, izindawo zokugcina ukushisa zisebenzisa abalandeli njengama-evaporators, abonakala ngesivinini sokupholisa ngokushesha, kodwa kulula ukubangela ukulahlekelwa umswakama wemikhiqizo efrijini; izindawo ezibandayo ezibandayo ezisezingeni eliphakathi nendawo neziphansi ikakhulukazi zisebenzisa amapayipi ahwamukayo enziwe ngamapayipi ensimbi angenamthungo, abonakala ngokuthi Umphumela wokushisa oqhubekayo muhle, futhi ungagcina amakhaza ngesikhathi.

I-Condenser:

I-condenser inezindlela zokupholisa komoya, ukupholisa amanzi kanye nezindlela zokupholisa ezihlangene zomoya namanzi. Ukupholisa komoya kunqunyelwe ezintweni ezincane zokugcina ezibandayo, kuyilapho ama-condenser apholile ngamanzi angasetshenziswa kuzo zonke izinhlobo zezinhlelo zesiqandisi.

I-valve yokwandisa:

I-valve yokwandisa okushisayo ihlukaniswe i-valve yangaphakathi yokwandisa ibhalansi kanye ne-valve yokwandisa ibhalansi yangaphandle. Ukucindezela kwe-inlet ye-evaporator kuzwakala ngaphansi kwe-diaphragm ye-valve yokwandisa ibhalansi yangaphakathi; ukuhwamuka kuzwakala ngaphansi kwe-diaphragm ye-valve yokwandisa ibhalansi yangaphandle. ingcindezi yokuphuma.

I-Accumulator :

gcina iFreon ukuze uqinisekise ukuthi isiqandisi sihlala sisesimweni esigcwele.

I-valve ye-Solenoid:

vimbela ingxenye yokucindezela okuphezulu koketshezi lwesiqandisi ukuthi ingangeni ku-evaporator lapho i-compressor imiswa, gwema ukucindezela okuphansi ukuthi kungabi phezulu kakhulu lapho i-compressor iqalwa ngokuzayo, futhi uvimbele i-compressor ekushaqekeni kwe-liquid. Ngaphezu kwalokho, lapho izinga lokushisa lesitoreji esibandayo lifinyelela inani elibekiwe, i-thermostat izosebenza, i-valve ye-solenoid izolahlekelwa amandla, futhi i-compressor izoyeka lapho ukucindezela okuphansi kufinyelela inani elibekiwe. Lapho ugesi uvuliwe, i-compressor iqala lapho ukucindezela kokucindezela okuphansi kukhuphukela ku-compressor isiqalo sokusetha inani.

Isivikeli sengcindezi ephezulu nephansi:

vikela i-compressor ekucindezelweni okuphezulu nokucindezela okuphansi.

I-Thermostat:

Ilingana nobuchopho bendawo yokugcina ebandayo elawula ukuvulwa nokuvalwa kwesiqandisi, ukuncishiswa kweqhwa, kanye nezifeni zesitoreji esibandayo.

Okomisa okokuhlunga:

hlunga ukungcola kanye nomswakama ohlelweni.

Isivikeli somfutho kawoyela:

Qinisekisa ukuthi i-compressor inamafutha okugcoba anele.

Isihlukanisi sikawoyela:

Umsebenzi wawo ukuhlukanisa amafutha okugcoba ku-steam ephezulu yokucindezela ekhishwe ku-compressor yesiqandisi ukuqinisekisa ukusebenza okuphephile nokusebenza kahle kwedivayisi. Ngokomgomo wokuhlukaniswa kwamafutha ngokunciphisa isivinini sokugeleza komoya kanye nokushintsha isiqondiso sokugeleza komoya, izinhlayiya zamafutha kumusi wokucindezela okukhulu zihlukaniswa ngaphansi kwesenzo samandla adonsela phansi. Ngokuvamile, lapho isivinini sokugeleza komoya singaphansi kuka-1m/s, izinhlayiya zikawoyela ezinobubanzi obungaphezu kuka-0.2mm obuqukethwe kusitimu zingahlukaniswa. Kunezinhlobo ezine zezihlukanisi zikawoyela ezivame ukusetshenziswa: uhlobo lokuwasha, uhlobo lwe-centrifugal, uhlobo lokupakisha kanye nohlobo lwesihlungi.

Isikhathi sokuthumela: Nov-14-2022