1. Yenza izimpawu ezinembile nezicacile ngokuhambisana nemidwebo yokwakha edwetshiwe;shisela noma ufake imishayo esekelayo, amakholomu, amafreyimu ensimbi asekelayo, njll., futhi amashisela azoba nobufakazi bomswakama futhi anqande ukubola ngokuhambisana nezidingo zemidwebo.

2. Izinto zokusebenza ezidinga ukufakwa endaweni yokugcina izinto futhi ezidinga ukungena endaweni yokugcina impahla kusenesikhathi zifakwa endaweni noma zibekwe endaweni efanele endaweni yokugcina impahla;

3. Faka izibani zesikhashana endaweni yokugcina impahla, faka futhi uhlele izinto zikagesi ezizokwakhiwa, futhi wenze umsebenzi omuhle wokuvikela emvuleni, emswakameni, ekungqubuzaneni, nasezintanjeni.

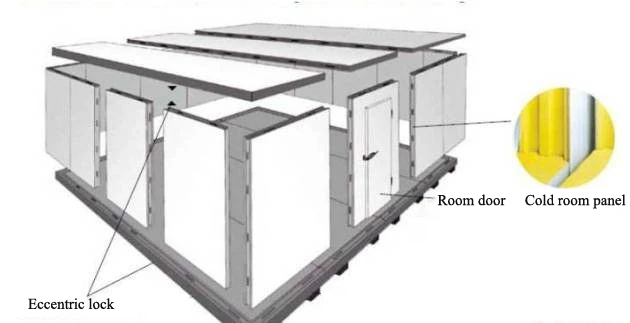

4. Faka ibhodi lokugcina elibandayo odongeni ukusuka ekhoneni lendawo yokugcina impahla, futhi ulungise isikhashana ikhoneni ngensimbi ye-angle yombala we-30×30×0.5;lapho ufaka i-wallboard ngayinye, wendlala izendlalelo ezimbili zezinto ezikhihliza amagwebu ngokulinganayo endaweni ehlangene yemisele yesilisa neyesifazane, bese ufaka umucu we-poly A wempahla egwazayo kusetshenziswa i-styrene wallboard.Ukondla kufanele kube okufanayo futhi kuqhubeke;ngemva kokufakwa kwamaphaneli odonga endaweni, ama-rivets asetshenziswa lapho kugqagqana khona amapuleti ensimbi angaphakathi nangaphandle amaphaneli amabili odonga azoxhunywa futhi alungiswe, futhi isikhala se-rivet kufanele sibe ngu-300mm endaweni yokugcina impahla;amaphaneli okugcina abandayo efomu lokuxhuma i-eccentric hook kufanele abe yi-eccentric ngaphambi kokufakwa I-hook ikhululiwe futhi ukuze kuqinisekiswe ukukhiya okuthembekile ngesikhathi sokufakwa.

5. Ukufakwa kwebhodi lokugcina elibandayo kufanele kwenziwe ngokushintshana nokufakwa kwebhodi lodonga, futhi ibhodi lodonga kufanele lishiywe ngaphandle kwegebe lokuhoxiswa kwemishini yokwakha;lapho kufakwa ibhodi lokugcina eliphezulu, isikhumba sensimbi ekupheleni kokugqagqana nebhodi lodonga kufanele sinqanyulwe ngo-50mm ukuvimbela "ibhuloho elibandayo" ekusebenzeni.Kubanda;Izendlalelo ezimbili zezinto ezinogwebu zishaywa ngokulinganayo endaweni ehlangene phakathi kwebhodi ngalinye lesitolo esiphezulu.Ukushaya kufanele kube okufanayo futhi okuqhubekayo.Izihlanganisi zamathanga phakathi kwezingxenye zangaphakathi nezingaphandle zepuleti lensimbi kufanele zilungiswe ngama-rivets.Ibanga phakathi kwama-rivets kufanele libe ngu-300mm;

6. Ukuze kuqinisekiswe ukuphepha kokwakhiwa kanye nokusebenza kwesitoreji esibandayo kanye nokusetshenziswa, ububanzi phakathi kwezisekelo ze-slab (amaphoyinti okuphakamisa) kufanele kuhlangabezane nalezi zidingo ezilandelayo:

Ibhodi lophahla lwe-polystyrene (ubukhulu obuyi-100mm) ne-span enkulu yamamitha angu-3;

Ubude besikhathi esiphezulu sebhodi lophahla lwe-polyurethane (ubukhulu obungu-100mm) bungamamitha angu-5.

7. Uma ufaka amapuleti aphezulu okugcina amakhaza aphezulu, uma imishayo yensimbi esekelayo ifakiwe endaweni yokugcina, amapuleti aphezulu okugcina kanye nemishayo yensimbi esekelayo kufanele ilungiswe ngama-rivets lapho ufaka ipuleti ngayinye yokugcina.Ipuleti ngalinye lokugcina eliphezulu kufanele lishaywe ngemigqa emibili kwezintathu.ama-Rivets;uma uhlobo lwephoyinti lokuphakamisa lwamukelwa, ukufakwa kanye nomsebenzi wokwakhiwa kwesakhiwo sokulenga kufanele kuqedwe ngaphambi kokufakwa kwe-slab ophahleni ukuze kuqinisekiswe ukuthi amaphuzu okuphakamisa angafakwa ngesikhathi esifanayo ngesikhathi sokufakwa kwe-roof slab;indawo yokuphakamisa kufanele iqinisekise ukuthi i-slab ngayinye ifakiwe Kukhona okungenani amaphuzu amabili ngobubanzi.

8. Izidunu zebhodi lokugcina elibandayo kanye nebhodi lokugcina elibandayo kufanele belashwe ukuze kuvinjelwe ukuvuza komoya nokugijima okubandayo.Ngemva kokuba ibhodi lomtapo wolwazi selifakwe ngokugcwele, amalunga ezinqe kufanele agcwaliswe ngezinto ezinegwebu, futhi ipuleti lensimbi elinombala obanzi ongu-80mm limbozwa emajoyini ezinqeni ngokudonsa i-riveting.

9. Lapho ufaka umzimba womtapo wezincwadi we-polystyrene, iphutha lokuma kwebhodi lodonga kufanele lilungiswe ngenkathi kufakwa ibhodi lomtapo wolwazi ophezulu.Ubude bebhodi lendlu yokugcina impahla kufanele bube bufushane ngo-10mm kunobuso obungaphandle bebhodi lodonga.Ngemva kokufakwa kwebhodi lesitolo esiphezulu, lapho ufaka ikona elingaphandle, igebe elingu-10mm kufanele limakwe ngegwebu ukuze kuqinisekiswe ukusebenza kokuvala kwendlu yokugcina izinto.

10. Uma ibhodi lokuphahla noma ibhodi lodonga lidinga ukubhoboza, ukubeka umugqa wangaphakathi nangaphandle kufanele kwenziwe ngokuvumelana nezidingo zokuklama komdwebo, futhi imigodi kufanele ivulwe ngemva kokuba isheke lilungile;imbobo yokungena ngomugqa, imbobo yoketshezi, imbobo yokubuyisela umoya, imbobo yamanzi, kanye nembobo yokukhipha amanzi Sebenzisa isaha lembobo ukwenza imigodi.Yenza ukwelashwa kokwakhiwa ngesikhathi ngemuva kokuvula umgodi.Sebenzisa impahla yegwebu noma i-sealant ukuze uvale imbobo ukuvimbela ukuvuza komoya futhi kubanda;iminyango, ama-vents, kanye nezikhala zempahla zihlotshiswe ngokuhlelwa futhi zihlanganiswe nama-rivets.Ibanga phakathi kwama-rivets ngu-300mm ngaphakathi kanye ne-150mm ngaphandle..

11. Ibanga phakathi kwama-rivets ekhoneni langaphakathi nangaphandle lingu-300mm no-200mm ngokulandelana;ngemuva kokufakwa komzimba womtapo we-polystyrene, amalunga amabhodi wodonga ahlanganiswe ngokulinganayo futhi ahlotshiswe nge-silicone sealant.

12. Phakathi nenqubo yokuhlola umshini wokuhlola isitoreji esibandayo, othile kufanele ahlole ukuthi indawo engaphandle yebhodi yokugcina kufanele ibonakale ngendlela efanayo, ingafinyeleli futhi isebenze ngokubanda;hlola izimo zokuvala amalunga, ukuvuleka nokubhoboza;kungakhathaliseki ukuthi iminyango yokugcina impahla, izikhumulo zemikhumbi, njll. zivaliwe Endabeni yezimo ezixegayo, ukubhekana ngesikhathi nezinkinga zokukhishwa kwe-degumming, ukuvuza komoya nokunye ukugcinwa kokushisa nokuhluleka kokuvala.

Isikhathi sokuthumela: Nov-29-2021