Kunezindlela eziningi zokuqandisa, futhi ezilandelayo zivame ukusetshenziswa:

1. Isiqandisi sokuhwamuka kwamanzi

2. Ukunwetshwa kwegesi nesiqandisi

3. Isiqandisi se-Vortex tube

4. Ukupholisa i-thermoelectric

Phakathi kwazo, i-liquid vaporization refrigeration isetshenziswa kakhulu. Isebenzisa umphumela wokumunca ukushisa wokuhwamuka koketshezi ukuze kufinyelele isiqandisi. Ukucindezelwa komhwamuko, ukumuncwa, umjovo womhwamuko kanye nesiqandisi se-adsorption konke kuyifriji ekhipha umhwamuko ewuketshezi.

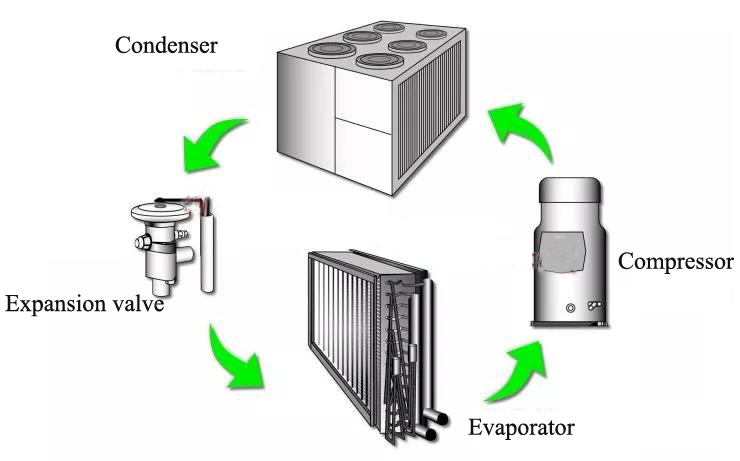

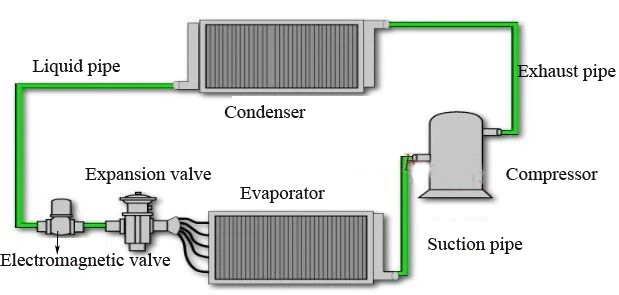

Isiqandisi sokuminyanisa umhwamuko singokwesigaba sokushintsha kwesiqandisi, esisebenzisa umphumela wokumunca ukushisa lapho isiqandisi sishintsha sisuka oketshezini siye kugesi ukuze sithole amandla abandayo. Yakhiwe izingxenye ezine: i-compressor, i-condenser, i-throttling mechanism kanye ne-evaporator. Axhunywe ngokushintshana ngamapayipi ukuze enze uhlelo oluvaliwe.

Izingxenye zesiqandisi eziyinhloko nezesekeli

1.I-Compressor

Ama-compressor ahlukaniswe abe yizakhiwo ezintathu: uhlobo oluvulekile, uhlobo oluvulekile, kanye nohlobo oluvaliwe. Umsebenzi we-compressor ukumunca isiqandisi esinezinga lokushisa eliphansi ukusuka ohlangothini lwe-evaporator, bese usicindezela sibe yi-high-pressure, high-temperature refrigerant vapor bese usithumela ku-condenser.

2.I-Condenser

I-condenser iyithuluzi lokushintshanisa ukushisa elidlulisa umthamo wesiqandisi we-evaporator ohlelweni lwesiqandisi kanye nomsebenzi wenkomba yokucindezela we-compressor endaweni yemvelo (amanzi okupholisa noma umoya). Ngokwendlela yokupholisa, i-condenser ingahlukaniswa ibe yi-air-cooled, epholile ngamanzi kanye ne-evaporative. I-condenser iyithuluzi lokushintshanisa ukushisa elidlulisa umthamo wesiqandisi we-evaporator ohlelweni lwesiqandisi kanye nomsebenzi wenkomba yokucindezela we-compressor endaweni yemvelo (amanzi okupholisa noma umoya). Ngokwendlela yokupholisa, i-condenser ingahlukaniswa ibe yi-air-cooled, epholile ngamanzi kanye ne-evaporative.

3. I-Evaporator

I-evaporator isho ukuthi uketshezi oluyisiqandisi luyabila futhi lumunce ukushisa kwendawo epholile (umoya noma amanzi) ezingeni lokushisa eliphansi ukuze kufezwe injongo yesiqandisi.

4. I-valve ye-Solenoid

I-valve ye-Solenoid uhlobo lwe-valve yokuvala evuleka ngokuzenzakalelayo ngaphansi kokulawulwa kukagesi. Ivamise ukufakwa epayipini lesistimu ukuze ivule futhi ivale ngokuzenzakalelayo i-actuator yesilawuli sezindawo ezimbili sepayipi lesistimu yesiqandisi. I-valve ye-solenoid ivame ukufakwa phakathi kwe-valve yokwandisa kanye ne-condenser. Indawo kufanele ibe seduze kakhulu nevalvu yokunweba, ngoba i-valve yokunweba imane nje iyisici esidonsayo futhi ayikwazi ukuzivaleka ngokwayo, ngakho-ke i-solenoid valve kufanele isetshenziselwe ukunqamula ipayipi lokuhambisa uketshezi.

5.I-valve yokwandisa ukushisa

Imishini yesiqandisi ivamise ukusebenzisa ama-valve okwandisa ukushisa ukuze kulungiswe ukugeleza kwesiqandisi. Akuyona kuphela i-valve elawulayo elawula ukunikezwa kwamanzi kwe-evaporator, kodwa futhi i-valve ye-throttle yedivayisi yesiqandisi. I-valve yokwandisa okushisayo isebenzisa ushintsho ekushiseni okuphezulu kwesiqandisi ekuphumeni kwe-evaporator ukuze ilungise ukunikezwa koketshezi. I-valve yokwandisa okushisayo ixhunywe epayipini lokungena eliwuketshezi le-evaporator, futhi i-bulb ezwa izinga lokushisa ibekwe epayipini lokuphuma kwe-evaporator (i-outlet). Imvamisa ihlukaniswe ngezakhiwo ezahlukahlukene ngokuya ngesakhiwo se-valve yokwandisa ukushisa:

(1) I-valve yokunweba eshisayo elinganiselwe ngaphakathi;

(2) I-valve yokwandisa okushisayo elinganiselayo ngaphandle.

I-valve yokwandisa okushisayo elinganiselayo ngaphakathi: Yakhiwa i-bulb ezwa izinga lokushisa, ithubhu ye-capillary, isihlalo se-valve, i-diaphragm, i-ejector rod, inaliti ye-valve kanye nendlela yokulungisa. Ama-valve alinganiswe ngaphakathi okunweba okushisayo ngokuvamile asetshenziswa kuma-evaporator amancane.

I-valve yokwandisa okushisayo elinganiselayo ngaphandle: Ivalvu enwebekayo yangaphandle eshisayo Emapayipini ahwamuzayo anamapayipi amade noma ukumelana kakhulu, kuvame ukusetshenziswa amavalvu okwandisa ukushisa alinganiswe ngaphandle. Ku-evaporator yobukhulu obufanayo, i-valve yokwandisa elinganiselwe ngaphakathi ingasetshenziswa lapho isetshenziswa endaweni yokugcina izinga lokushisa eliphezulu, kuyilapho i-valve yokwandisa elinganiselayo ngaphandle ingasetshenziswa uma isetshenziswa endaweni yokugcina izinga lokushisa eliphansi. Ku-evaporator yobukhulu obufanayo, i-valve yokwandisa elinganiselwe ngaphakathi ingasetshenziswa lapho isetshenziswa endaweni yokugcina izinga lokushisa eliphezulu, kuyilapho i-valve yokwandisa elinganiselayo ngaphandle ingasetshenziswa uma isetshenziswa endaweni yokugcina izinga lokushisa eliphansi.

6. Isihlukanisi samafutha

Isihlukanisi samafutha ngokuvamile sifakwa phakathi kwe-compressor kanye ne-condenser ukuze kuhlukaniswe uwoyela womshini wesiqandisi ofakwe kumoya wesiqandisi. Idivaysi yokubuyisela uwoyela isetshenziselwa ukubuyisela uwoyela womshini oqandisayo ku-crankcase ye-compressor; isakhiwo esivame ukusetshenziswa sesihlukanisi samafutha sinezinhlobo ezimbili: uhlobo lwe-centrifugal nohlobo lokuhlunga.

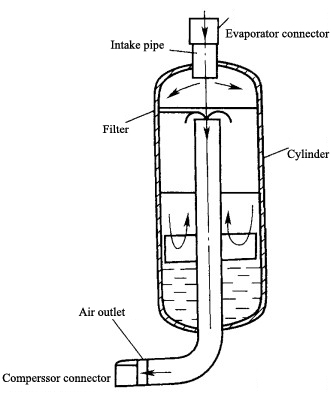

7. Isihlukanisi segesi-uketshezi

Hlukanisa isiqandisi segesi esiqandisini esiwuketshezi ukuvimbela i-compressor kwisando esiwuketshezi; gcina uketshezi lwesiqandisi emjikelezweni wesiqandisi, futhi ulungise ukunikezwa kwamanzi ngokuvumelana noshintsho lomthwalo.

8. Ichibi

Ngokusetha i-accumulator, umthamo wokugcina uketshezi we-accumulator ungasetshenziswa ukulinganisa nokuzinzisa ukujikeleza kwesiqandisi ohlelweni, ukuze idivayisi yesiqandisi isebenze ngokujwayelekile. I-accumulator ngokuvamile isethwe phakathi kwe-condenser kanye nento eshayayo. Ukuze isiqandisi se-liquid ku-condenser singene ku-accumulator kahle, isikhundla se-accumulator kufanele sibe ngaphansi kune-condenser.

9. Isomisi

Ukuze uqinisekise ukujikeleza okuvamile kwesiqandisi, uhlelo lwesiqandisi kufanele lugcinwe luhlanzekile futhi lomile. Umshini wokomisa isihlungi uvamise ukufakwa ngaphambi kwe-elementi ye-throttling. Lapho isiqandisi esiwuketshezi siqala sidlula endaweni yokomisa isihlungi, singavimbela ngempumelelo ukuvaleka kwento edonsayo.

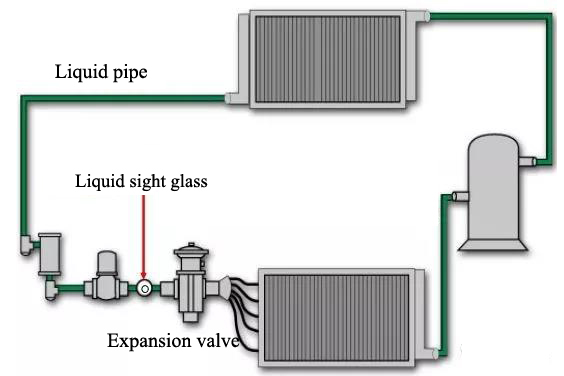

10. Ingilazi yokubuka

Ngokuyinhloko isetshenziselwa ukukhombisa isimo sefriji epayipini le-liquid ledivayisi yesiqandisi kanye nokuqukethwe kwamanzi esiqandisini. Ngokuvamile, imibala ehlukene imakwa endaweni yengilazi yokubona ukuze ibonise okuqukethwe kwamanzi esiqandisini ohlelweni.

11. High and low voltage relay

Uma ingcindezi yokukhishwa kwe-compressor iphezulu kakhulu, izonqamula ngokuzenzakalelayo, imise i-compressor futhi isuse imbangela yokucindezela okukhulu, bese usetha kabusha ngesandla ukuze uqale i-compressor (iphutha + i-alamu); lapho ingcindezi yokuncela yehlela emkhawulweni ophansi, izonqamula ngokuzenzakalelayo. Misa i-compressor, bese unika i-compressor amandla futhi lapho ingcindezi yokudonsa ikhuphukela kumkhawulo ongaphezulu.

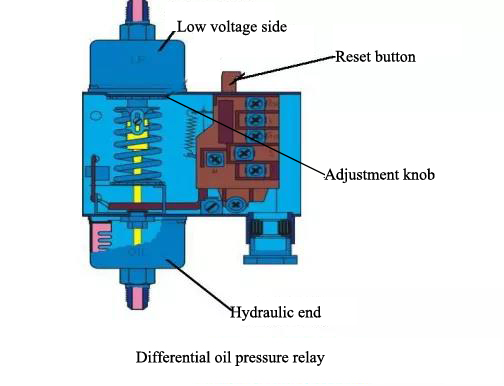

12. Umehluko we-oyela yokucindezela uwoyela

Iswishi kagesi esebenzisa umehluko wengcindezi phakathi kokumunca nokukhishwa kwepompo likawoyela wokugcoba njengesignali yokulawula, lapho umehluko wengcindezi ungaphansi kwevelu ebekiwe, imisa i-compressor ukuze iyivikele.

13. Ukudlulisa izinga lokushisa

Sebenzisa izinga lokushisa njengesignali yokulawula ukuze ulawule izinga lokushisa lendawo ebandayo. Ukuqala nokuma kwe-compressor kungalawulwa ngokuqondile ngokulawula ukuvula nokuvala i-valve ye-solenoid ewuketshezi; lapho umshini owodwa unamabhange amaningi, ukudluliselwa kwezinga lokushisa kwebhange ngalinye kungaxhunywa ngokuhambisana ukuze kulawulwe ukuqala okuzenzakalelayo nokuma kwe-compressor.

14. Isiqandisi

Iziqandisi, ezaziwa nangokuthi iziqandisi neziqandisi, ziyizinto zemidiya ezisetshenziswa ezinjinini zokushisa ezehlukene ukuqedela ukuguqulwa kwamandla. Lezi zinto ngokuvamile zisebenzisa ukuguqulwa kwesigaba esibuyiseleka emuva (njengokushintsha kwesigaba soketshezi lwegesi) ukuze kukhuliswe amandla.

15. Amafutha esiqandisini

Umsebenzi wamafutha omshini wokuqandisa ngokuyinhloko uwukugcoba, ukuvala, ukupholisa nokuhlunga. Kuma-multi-cylinder compressor, uwoyela wokugcoba ungasetshenziswa futhi ukulawula indlela yokuthulula.

Isikhathi sokuthumela: Nov-15-2021