1.Qala uqale futhi ume

Ngaphambi kokuqala, inhlanganisela kufanele ihlanganiswe.Uma uqala okokuqala, kufanele uqale uhlole izimo zokusebenza zazo zonke izingxenye ze-compressor nezingxenye zikagesi.

Izinto zokuhlola zimi kanje:

a.Vala iswishi yamandla bese ukhetha ukuma okwenziwa ngesandla kweswishi yesikhethi;

b.Cindezela inkinobho ye-alamu, insimbi ye-alamu izokhala;cindezela inkinobho yokuthula, i-alamu izoqedwa;

c, Cindezela inkinobho yokushisisa kagesi futhi ukukhanya kwenkomba kuvuliwe.Ngemva kokuqinisekisa ukuthi i-heater kagesi iyasebenza, cindezela inkinobho yokumisa ukushisa futhi ukukhanya kwenkomba yokushisa kuvaliwe;

d.Cindezela inkinobho yokuqalisa iphampu yamanzi, iphampu yamanzi iyaqala, ukukhanya kwenkomba kuvuliwe, cindezela inkinobho yokumisa iphampu yamanzi, iphampu yamanzi iyama, nokukhanya kwenkomba kuvaliwe;

e.Cindezela inkinobho yokuqala yephampu kawoyela, ukukhanya kwephampu kawoyela kuvuliwe, iphampu kawoyela iyasebenza futhi ijikeleza ngendlela efanele, futhi umehluko wengcindezi kawoyela ulungiswa ube ngu-0.4~0.6MPa.Phenya i-valve yezindlela ezine noma cindezela inkinobho yokwandisa/ukwehlisa umthwalo ukuze uhlole ukuthi ivalve yesilayidi nedivayisi ebonisa amandla isebenza ngokujwayelekile, futhi inkomba yokugcina yezinga lamandla isendaweni ethi “0″.

Hlola inani elimisiwe lokudluliselwa ngakunye kokuvikela ukuphepha okuzenzakalelayo noma uhlelo/Izinga lokushisa le-compressor nenani lereferensi yokuvikela ukucindezela:

a.Ukuvikelwa komfutho we-exhaust ephezulu: ingcindezi yokukhipha≦1.57MPa

b.Ukuvikelwa kwezinga lokushisa lomjovo wamafutha aphezulu: izinga lokushisa lomjovo kaphethiloli≦65℃

c.Ukuvikelwa komehluko wengcindezi kawoyela ephansi: umehluko wengcindezi kawoyela ≧0.1MPa

d.Ukuvikelwa komehluko wengcindezi ephezulu ngaphambi nangemuva kwesihlungi esihle: umehluko wengcindezi≦0.1MPa

e.Ukuvikelwa kokucindezela okuphansi kokumunca: kusethwa ngokuya ngezimo zangempela zokusebenza

Ngemva kokuhlola izinto ezingenhla, ingavulwa

Ngemva kokuhlola izinto ezingenhla, ingavulwa

Izinyathelo zokuvula zimi kanje:

a.Iswishi yesikhethi ivulwa ngokwenza;

b.Vula i-valve yokuvala i-compressor;

c.Yehlisa i-compressor endaweni ethi “0″, okuyisikhundla sokulayisha esingu-10%;

d.Qala iphampu yamanzi okupholisa kanye nepompo yamanzi efrijini ukuze unikeze amanzi ku-condenser, i-oil cooler kanye ne-evaporator;

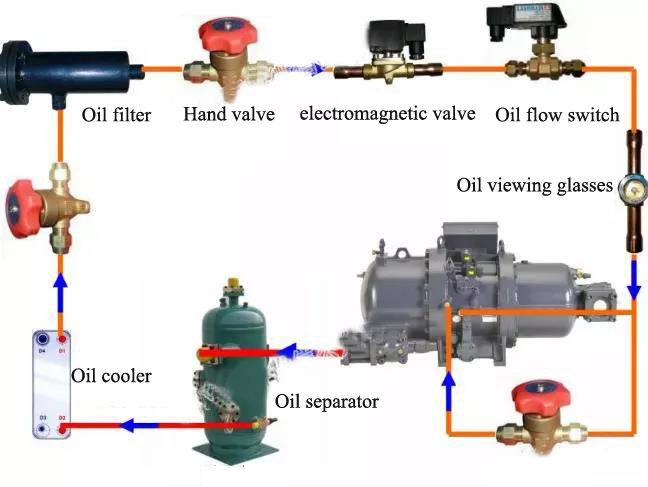

e.Qala iphampu yamafutha;

f.Imizuzwana engu-30 ngemva kokuba iphampu yamafutha iqalisiwe, umehluko phakathi kokucindezela kwamafutha kanye nokucindezela kokukhipha kufinyelela ku-0.4 ~ 0.6MPa, cindezela inkinobho yokuqala ye-compressor, i-compressor iqala, futhi i-bypass solenoid valve A iphinde ivule ngokuzenzakalelayo.Ngemuva kokuthi injini isebenze ngokujwayelekile, i-valve engu-A ivalwa ngokuzenzakalelayo;

g.Bheka igeji yokudonsa ingcindezi, vula kancane kancane ivalvu yokumisa ukumunca bese ukhuphula umthwalo mathupha, futhi unake ingcindezi yokudonsa ukuze ingabi phansi kakhulu.Ngemuva kokuthi i-compressor ingene ekusebenzeni okujwayelekile, lungisa i-valve elawula umfutho kawoyela ukuze umehluko wengcindezi kawoyela ube ngu-0.15 ~ 0.3MPa.

h.Hlola ukuthi ukucindezela kanye nezinga lokushisa kwengxenye ngayinye yemishini, ikakhulukazi izinga lokushisa lezingxenye ezihambayo, lijwayelekile.Uma kukhona okungavamile, misa umshini ukuze uhlolwe.

i.Isikhathi sokuqala sokusebenza akufanele sibe side kakhulu, futhi umshini ungavalwa cishe ngesigamu sehora.Ukulandelana kokuvala shaqa kuwukuthulula, kumise umsingathi, ukuvala ivalve yokuvala ukudonsa, kumise iphampu kawoyela, futhi kumise iphampu yamanzi ukuze kuqedelwe inqubo yokuqala yokuqalisa.Lapho inkinobho yokumisa injini enkulu icindezelwa, i-bypass solenoid valve B ivuleka ngokuzenzakalelayo, futhi i-valve B ivaleka ngokuzenzakalelayo ngemva kokuvalwa.

2.Ukuqalisa okujwayelekile kanye nokuvala shaqa

Ukuqala okujwayelekilekukhonaNgokulandelayo:

Khetha i-boot manual, inqubo iyafana ne-boot yokuqala.

Khetha ukuvula amandla okuzenzakalelayo:

1) Vula i-valve yokuvala i-compressor exhaust, qala iphampu yamanzi okupholisa kanye nepompo yamanzi efriji;

2) Cindezela inkinobho yokuqala ye-compressor, khona-ke iphampu kawoyela izofakwa ngokuzenzakalelayo ekusebenzeni, futhi i-spool valve izobuyela ngokuzenzakalelayo endaweni ethi "0".Ngemva kokusungulwa komehluko wengcindezi kawoyela, injini eyinhloko izoqala ngokuzenzakalelayo ngemva kokubambezeleka kwemizuzwana eyi-15, futhi i-bypass solenoid valve A izovuleka ngokuzenzakalelayo ngesikhathi esifanayo.Ngemuva kokuthi injini isebenze ngokujwayelekile, i-valve engu-A ivalwa ngokuzenzakalelayo;

3) Lapho injini eyinhloko iqala ukuqala, i-valve yokuvala ukudonsa kufanele ivuleke kancane ngesikhathi esifanayo, ngaphandle kwalokho i-vacuum ephezulu kakhulu izokwandisa ukudlidliza nomsindo womshini.

I-4) I-compressor izokwandisa ngokuzenzakalelayo umthwalo ku-100% futhi ifake isimo esivamile sokusebenza.Futhi ulungise ngokuzenzakalelayo indawo yomthwalo ngokuya ngenani lokusetha ingcindezi noma inani lokusetha izinga lokushisa esiqandisini.

Inqubo evamile yokuvala shaqa imi kanje:

Ukuvala shaqa mathupha kuyafana nenqubo yokuvala yokuqalisa kokuqala.

Iswishi yesikhethi isendaweni ezenzakalelayo:

1) Cindezela inkinobho yokumisa i-compressor, i-valve yesilayidi izobuyela ngokuzenzakalelayo ku-"0" isikhundla, injini eyinhloko izoma ngokuzenzekelayo, futhi i-bypass solenoid valve B izovuleka ngokuzenzakalelayo ngesikhathi esifanayo, iphampu kawoyela izoma ngokuzenzakalelayo ngemva ukubambezeleka, futhi i-valve engu-B izovala ngokuzenzakalelayo ngemva kokuma;

2) Vala ivalvu yokumisa ukumunca.Uma ivaliwe isikhathi eside, i-valve yokuvala i-exhaust kufanele iphinde ivalwe;

3) Vala inkinobho yamandla yepompo yamanzi kanye ne-compressor.

3. Izinyathelo zokuqapha ngesikhathi sokusebenza

1) Naka ukubuka ingcindezi yokuncela nokukhipha, izinga lokushisa lokumunca kanye nokukhipha, izinga lokushisa likawoyela kanye nomfutho kawoyela ngesikhathi sokusebenza kwe-compressor, futhi urekhode njalo.Imitha iyadingeka ukuze inembile.

I-2) I-compressor izomisa ngokuzenzakalelayo ngenxa yesenzo esithile sokuvikela ukuphepha ngesikhathi sokusebenza kwe-compressor, futhi imbangela yokungasebenzi kahle kufanele itholakale ngaphambi kokuba ivulwe.Ayivunyelwe ukuthi ivuleke futhi ngokushintsha izilungiselelo zayo noma amaphutha okuvikela.

3) Lapho injini eyinhloko ivala ngenxa yokuhluleka kwamandla kungazelelwe, i-compressor ingase ihlehle ngoba i-bypass solenoid valve B ayikwazi ukuvulwa.Ngalesi sikhathi, i-valve yokumisa ukumunca kufanele ivalwe ngokushesha ukuze kuncishiswe ukuhlehla.

I-4) Uma umshini uvaliwe isikhathi eside ngenkathi yokushisa ephansi, wonke amanzi ohlelweni kufanele akhishwe ukuze agweme ukulimala okubandayo kwemishini.

I-5) Uma uqala umshini ngesikhathi sokushisa okuphansi, qala uvule iphampu kawoyela, bese ucindezela i-motor ukuze ujikeleze isondo lokuqondisa ukuze uhambise ukuhlangana ukuze uwoyela ujikeleze ku-compressor ukuze uthole ukuthambisa okwanele.Le nqubo kumele yenziwe ngemodi yokuqalisa ngesandla;uma kuyi-Freon refrigerant, qala umshini Ngaphambi kokuvula i-heater kawoyela ukushisa amafutha okugcoba, izinga lokushisa likawoyela kufanele libe ngaphezu kuka-25℃.

6) Uma iyunithi ivaliwe isikhathi eside, iphampu yamafutha kufanele ivulwe njalo ezinsukwini ezingu-10 noma ngaphezulu ukuze kuqinisekiswe ukuthi kukhona amafutha okugcoba kuzo zonke izingxenye ze-compressor.Isikhathi ngasinye lapho iphampu yamafutha ivuliwe imizuzu engu-10;i-compressor ivulwa kanye njalo ezinyangeni ezi-2 kuya kwezi-3, njalo ngehora elingu-1.Qinisekisa ukuthi izingxenye ezihambayo azihlangani.

I-7) Ngaphambi kokuqala isikhathi ngasinye, kungcono ukujikeleza i-compressor izikhathi ezimbalwa ukuze uhlole ukuthi i-compressor ivinjiwe noma cha, nokusabalalisa amafutha okugcoba ngokulinganayo kuzo zonke izingxenye.

Isikhathi sokuthumela: Nov-22-2021